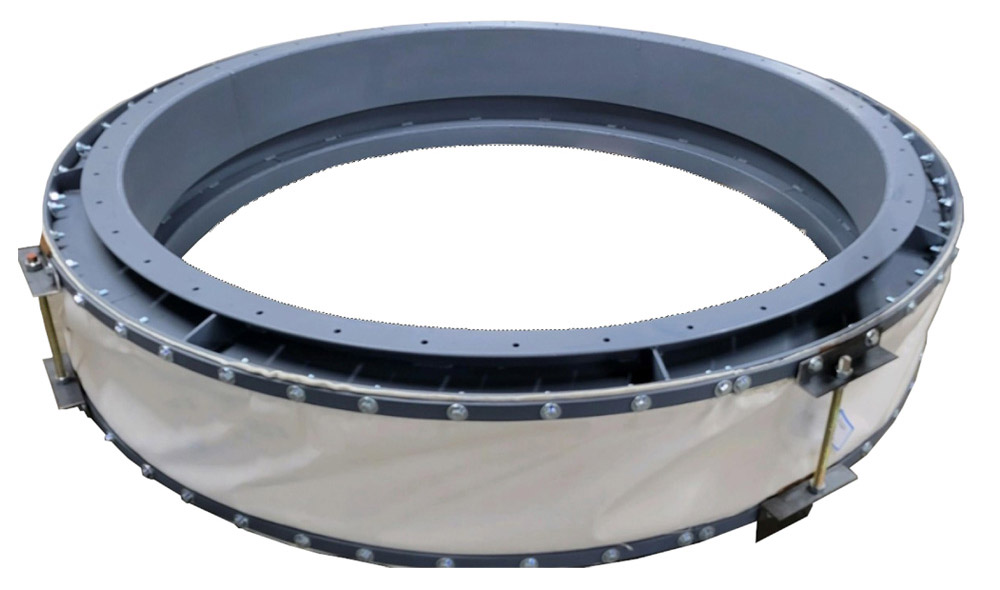

Expansion Joints

Non- Metallic Expansion Joints or also commonly known as Fabric Expansion Joints play a critical role in industrial process control systems due their ability of accommodating dynamic forces simultaneously.

Including:

Material Composition

- Made from high-quality, flexible materials such as fabrics, textiles, elastomers, and metal reinforcements. The choice of materials depends on the specific requirements of the application, including temperature, chemical exposure, and pressure.

Flexibility

- Industrial fabric expansion joints are highly flexible, allowing them to absorb movements and deformations. This flexibility helps prevent damage to the connected components and ensures the integrity of the overall system movements, fabric expansion joints help prevent stress and damage to the connected equipment.

Thermal Compensation

- One of the primary purposes is to compensate for Axial thermal expansion and Compression that occur during system service and upon an upset condition.

Vibration Isolation

- Fabric expansion joints also provide a degree of vibration isolation, reducing the transmission of vibrations and noise between connected components. This is particularly important in industrial settings where vibrations can impact the integrity and performance of the system.

Application Areas

- Industrial fabric expansion joints are commonly used in various industries, including power generation, petrochemical, chemical processing, heat recovery, VOC destruction, automotive and other applications involving industrial ducting.