Automation Packages

Pick & Choose Your Package

Dampers can be manually operated or automated using nearly any electric, pneumatic, or hydraulic actuator available. Direct or remote mounting are typical. MPF will supply the automation or install customer supplied packages.

Equipped With

Damper Accessories

- Blow Out & Drain Ports

- Inlet Weather Hoods

- Safety & Pinch Guards

- Carbide Blade Tips

- Position Feedback Components

- Control Enclosures & Other Junction Boxes

- Insulation / Cladding

- LOTO Brackets / Mechanical Lock Outs / Holsters

- Remote Pedestals / Drive Linkage

- Shaft Shields / Seat Shields

- Thermal Couplings / Heat Shields / Dissipating Rings

- Flow Regulators / Speed Fittings / Directional Solenoids

- Lubrication Extensions / Automatic Grease Loops

- Thrust Bearings / Cam Collars / Flow Arrows

- Specialty Travel or Rotation Limiters

(Consult Factory For Additional Information and Features)

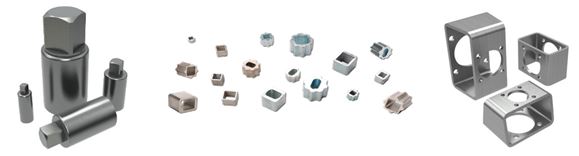

Machining & Automation

MPF is a full-service automation shop and CNC machining center with seasoned machinists, actuator technicians, CAD detailers, software technicians, and other talented team members. We design and manufacture our own bracketry, couplings, inserts, drive shafts, linkage kits, and other interface components. We can match existing designs or develop entirely new configurations while adhering to industry standards such as ISO 5210, 5211, 22109, 22153, etc…

Communication Interfaces

Automation packages can support various industrial communication protocols such as Modbus, Profibus, or Foundation Fieldbus, HART, etc., for seamless integration with other components in the industrial control system. These are common Ethernet-based communication protocols used in industrial automation for high-speed data exchange. Today’s technology provides touchscreen displays, Bluetooth, and other user-friendly interface for operators to monitor and control damper positions, setpoints, and system status. Physical control panels may be included for manual override, local control capabilities and monitoring allowing operators to access and adjust damper settings from a central control room or even remotely through secure connections.

Some of the Manufactures We Use

Emergency Shutdown (ESD)

Safety features are often included in automation packages for critical failure situations. For example, some processes rely on the fast acting, low leakage dampers to fail close (or open) to prevent severe, potentially catastrophic damage to the system. Fail safe type actuators have stored energy which is released upon a power loss forcing the damper to its de-energized state. Spring return type actuators are quite common, especially pneumatic rack and pinion types due to their reliability and low overall cost. Battery backup devices, ultra capacitors units, accumulators and other packages are available.

Factory Calibration

MPF standard procedures include cycle testing every damper that leaves our factory. Tests are completed by MPF’s trained technicians which make the necessary adjustments to the damper and/or its operator ensuring proper functionality and maximum performance prior to shipment. Our products are delivered with IOM manuals, certified cycle reports, and other documents depending upon equipment type and other specifications.